SMC02 Stepper Motor Driver & Pulse Generator Controller Board - With Manual Direction & Speed Control

Stepper Motor Direction & Signal Frequency Speed Control

ZK-SMC02 Stepper Motor Controller + Driver (Integrated)

Internal Reference:

KIT.STEPPER.PULSE.SMC02

ZK-SMC02 Stepper Motor Controller + Driver (Integrated)

Stepper Motor Driver & Pulse Generator Controller Board with Manual Direction & Speed Control

Product Overview

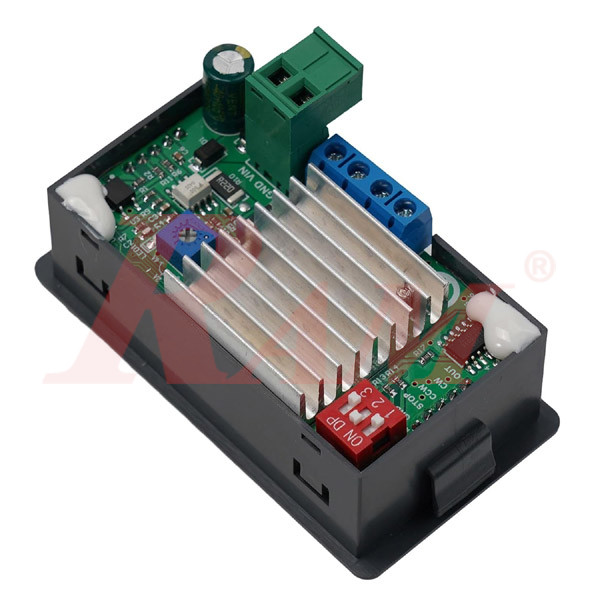

The ZK-SMC02 is an all-in-one stepper motor controller and driver designed for single-axis stepper motor control. It integrates motion control logic, pulse generation, and a high-current stepper driver in one compact module.

The controller supports manual operation, automatic operation, parameter setting, and TTL serial (MODBUS-RTU) control, and can operate independently without any external PLC or MCU. All motion parameters (distance, speed, delay, cycles, acceleration) are saved in non-volatile memory and retained after power loss.

Key Features

- Integrated stepper motor controller + driver (no external driver required)

- Single-axis motion control

- Forward / Reverse rotation control

- Manual control via front panel buttons and rotary encoder

- Automatic cycle operation with programmable distance, delay, and loops

- Acceleration & deceleration control

- Pulse-based positioning (high precision)

- Non-volatile memory (parameters saved after power-off)

- TTL serial communication (MODBUS-RTU protocol)

- Reverse polarity protection on power input

- Designed for general industrial control applications

Electrical & System Specifications

Parameter | Specification |

|---|---|

| Model | ZK-SMC02 |

| Type | Stepper Motor Controller + Driver (Integrated) |

| Control Axes | 1 (Single Axis) |

| Compatible Motors | Stepper motors (2-phase; supports 4-wire, 5-wire, 6-wire, 8-wire) |

| Motor Signal Type | Common cathode |

| Power Supply Voltage | DC 10 – 30 V |

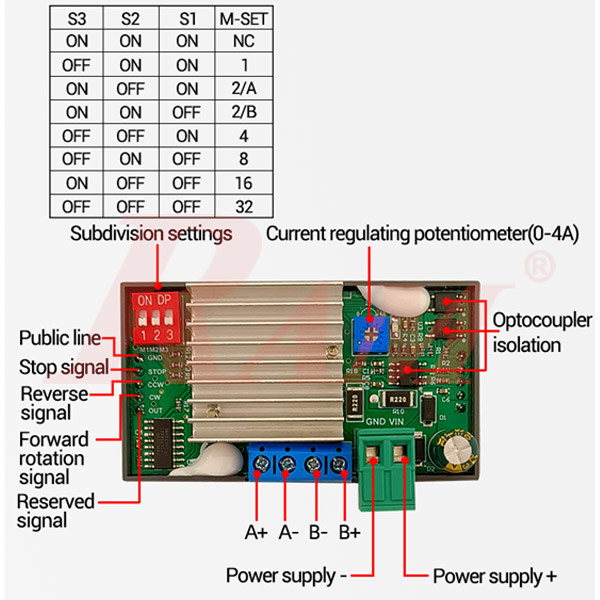

| Maximum Drive Current | 4 A |

| Acceleration / Deceleration | Supported (adjustable) |

| Reverse Polarity Protection | Yes |

| Operating Temperature | –5 °C to +60 °C (non-condensing) |

| Application Type | General industrial control (not medical / safety-critical) |

Motion Control Parameters

Function | Range |

|---|---|

| Speed Range | 0.1 – 999 RPM |

| Forward Pulse Count | 1 – 9,999,999 pulses |

| Reverse Pulse Count | 1 – 9,999,999 pulses |

| Cycle Count | 0 – 9,999 cycles (0 = infinite loop) |

| Forward Delay Time | 0.0 – 999.9 s |

| Reverse Delay Time | 0.0 – 999.9 s |

| Microstepping (Subdivision) | 1 – 128 subdivisions |

| Acceleration Level | 1 – 100 (1 = slowest, 100 = fastest) |

Built-In Operation Modes (F-01)

The ZK-SMC02 includes 9 predefined motion flow modes, selectable via menu F-01:

- P01 – Motor follows rotary encoder (manual speed control)

- P02 – Rotate while button is pressed, stop on release

- P03 – Press once to rotate continuously, STOP to halt

- P04 – Fixed distance → delay → repeat (forward or reverse)

- P05 – Fixed distance cycles → return to zero

- P06 – Forward & reverse alternating cycles

- P07 – Rotate → release → delay → return to zero

- P08 – Time-based forward/reverse with delay and cycles

- P09 – Auto forward & reverse cycles on power-up

User Interface

Front Panel Controls

- CW button – Forward rotation

- CCW button – Reverse rotation

- RUN/STOP button – Start / pause / exit

- Rotary encoder – Speed & parameter adjustment

Display

- LCD shows speed, delay time, cycle count, and mode status

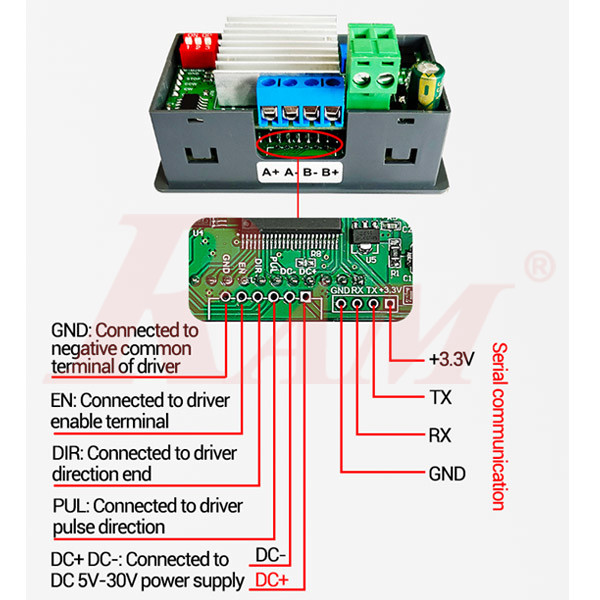

Serial Communication (TTL)

- Interface: TTL UART

- Protocol: MODBUS-RTU

- Supported Function Codes: 0x03, 0x06, 0x10

- Address Range: 1 – 255

- Supports remote control, parameter read/write, and run commands

Mechanical Specifications

Parameter | Value |

|---|---|

| Front Panel Size | 79 × 43 mm |

| Depth | 41 mm |

| Net Weight | 64 g |

| Weight (with packaging) | ≈ 90 g |

Typical Applications

- Automation fixtures

- Conveyor & indexing systems

- Linear motion platforms

- Rotating tables

- DIY & educational motion control

- General industrial stepper motor control

How to Set & Program the ZK-SMC02 Stepper Motor Controller

This controller is programmed entirely from the front panel using:

- Rotary encoder (knob)

- CW / CCW buttons

- RUN/STOP button

No computer is required.

1️⃣ Power On

- Connect DC 10–30V power supply

- Connect stepper motor to A+, A-, B+, B-

- The controller boots into the RUN (working) interface

2️⃣ Understanding the Two Interfaces

🔹 RUN Interface (Normal Operation)

Used during work:

- Shows speed, delay, or cycle count

- Knob adjusts speed

- CW / CCW buttons control direction

- RUN/STOP starts or stops motion

🔹 MENU Interface (Programming Mode)

Used to set all parameters:

- Accessed by long-pressing the rotary encoder

3️⃣ Enter Programming (MENU) Mode

- Make sure controller is stopped

- Long-press the rotary encoder

-

Display changes to:

F-01

You are now in menu setting mode

4️⃣ Select a Program (Motion Mode – F-01)

Step:

- When F-01 is shown

- Short-press the encoder

- Value starts flashing (P01 – P09)

- Rotate encoder to select mode

- Short-press encoder to confirm

Available Programs (F-01)

Mode | Description |

|---|---|

| P01 | Motor follows knob speed (manual) |

| P02 | Rotate while button is pressed |

| P03 | Press once → rotate continuously |

| P04 | Fixed distance → delay → repeat |

| P05 | Distance cycles → return to zero |

| P06 | Forward & reverse alternating |

| P07 | Rotate → release → delay → return |

| P08 | Time-based forward/reverse |

| P09 | Auto run after power-on |

5️⃣ Set Motion Parameters (F-02 to F-13)

Navigation

- Rotate encoder → select F-02 … F-13

- Short-press → edit value

- Rotate → change value

- Short-press → move to next digit

- RUN/STOP → exit parameter edit

🔧 Main Programming Parameters

F-02 – Forward Pulse Count

- Range: 1 – 9,999,999

- Sets forward movement distance

F-03 – Forward Speed

- Range: 0.1 – 999 RPM

F-04 – Reverse Pulse Count

- Range: 1 – 9,999,999

F-05 – Reverse Speed

- Range: 0.1 – 999 RPM

F-06 – Cycle Count

- 0 = infinite loop

- 1–9999 = fixed cycles

F-07 – Forward Delay Time

- 0.0 – 999.9 seconds

F-08 – Reverse Delay Time

- 0.0 – 999.9 seconds

F-09 – Pulses Per Revolution

Used to match motor + microstepping

Example:

- 1.8° motor

-

8 microsteps

→ 1600 pulses / rev

→ set F-09 = 160

F-10 – Display Mode

- 00 → speed + delay

- 01 → speed + cycle count

F-11 – Stop Mode

- 0 → smooth deceleration stop

- 1 → immediate stop (emergency)

F-12 – Acceleration Level

- 1 (slow) → 100 (fast)

F-13 – Serial Address

- 1 – 255 (used for TTL MODBUS)

6️⃣ Save Settings

- After finishing all parameters

- Long-press the rotary encoder

-

Controller:

- Saves settings

- Returns to RUN interface

⚠️ If you power off before long-press, settings will NOT be saved.

7️⃣ Start the Program

- Press CW → forward operation

- Press CCW → reverse operation

- Press RUN/STOP → pause / stop

Controller executes the selected F-01 program using your parameters.

8️⃣ Example: Simple Auto Forward & Reverse Loop

Goal:

- Forward 1600 pulses

- Delay 1 sec

- Reverse 1600 pulses

- Repeat forever

Settings:

F-01 = P06 F-02 = 1600 F-03 = 100 RPM F-04 = 1600 F-05 = 100 RPM F-06 = 0 F-07 = 1.0 F-08 = 1.0

Save → RUN → Press CW

✅ Programming Summary (Quick)

- Power ON

- Long-press knob → MENU

- Set F-01 program

- Set distance, speed, delay, cycles

- Long-press knob → SAVE

- RUN